Air strippers remove volatile contaminants from water by contacting air and water to optimize transfer kinetics. Common types of air strippers include packed towers, multi-stage bubble systems, venturi eductors, and spray nozzles.

DeepBubble ™ Systems

Lowry Engineering designs and manufactures multi-stage DeepBubble air strippers to remove volatile organics, radon, carbon dioxide, THM’s, methane, and hydrogen sulfide, and to oxidize iron for subsequent removal by filtration. DeepBubble™ models are offered to treat water supplies with flow rates ranging from a few gpm to over 2,000 gpm. The amount of removal is related to the A:W ratio; we select the appropriate design A:W ratio based upon years of research, modeling, and field experience. Treated water is discharged either by gravity into a clear well or pumped directly out of the air stripper vessel.

Our DeepBubble™ systems are engineered for simple and efficient operation, accessibility and ease of maintenance. All of our systems are less than 6 ft in height and can be easily installed in existing or standard buildings. In warmer climates, our systems can be installed and operated outdoors.

For hydrogen sulfide, we can selectively add carbon dioxide to our bubbles to lower pH in the first few stages. This enhances the rate and degree of sulfide removal. Excess carbon dioxide is stripped in the final stages.

In applications involving lowering pH in RO or CMF processes, carbon dioxide is added or produced by the addition of strong acids. DeepBubble™ systems are ideal for stripping the excess carbon dioxide post treatment.

In recent years, many DeepBubble™ systems have been used to provide a non-chemical solution to problems with corrosion (Pb & Cu) in distribution systems. The natural carbon dioxide is air-stripped and the pH is raised. We have treated supplies containing >200 mg/L carbon dioxide and eliminated use of existing corrosion control chemicals. Air-stripped water quality is superior to water quality after caustic and/or phosphate addition. Air stripping eliminates the need for corrosion control chemicals.

In recent years, many DeepBubble™ systems have been used to provide a non-chemical solution to problems with corrosion (Pb & Cu) in distribution systems. The natural carbon dioxide is air-stripped and the pH is raised. We have treated supplies containing >200 mg/L carbon dioxide and eliminated use of existing corrosion control chemicals. Air-stripped water quality is superior to water quality after caustic and/or phosphate addition. Air stripping eliminates the need for corrosion control chemicals.

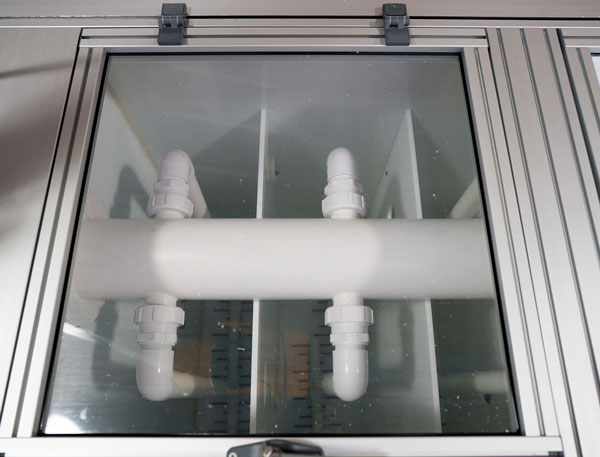

We have more than 30 years of experience with air strippers fabricated in various materials and in many operating environments. We fabricate our air strippers using an extrusion-welded HDPE (NSF61) tank that is insulated to created a low-sweat vessel. The vessel is supported by a non-rusting anodized aluminum profile frame. This gives our clients the best of all worlds - a corrosion-free vessel, a strong non-ferrous metal support frame, and a secure and easy to maintain and access system with lockable and hinged lids. .

At-A-Glance Product Specifications

| Model DB32 | Model DB63 | Model DB84 | Model DB86 | |

|---|---|---|---|---|

| Number of Stages | 3 | 6 | 8 | 8 |

| Max Flow, gpm | 150 | 500 | 1,200 | 1,800 |

| Max Air, scfm | 200 | 600 | 1,350 | 2,000 |

| Empty Weight, lb | 525 | 1,185 | 2,500 | 3,125 |

| Operating Weight, lb | 1,950 | 5,675 | 11,500 | 16,600 |

| Learn More | Learn More | Learn More | Learn More |